- Phase 1: Design

- Phase 2: Prefabrication

- Phase 3: Turnkey Assistance

Inspiration

Step1:

As you begin to think about constructing a custom system built house of your own, it is important to gather inspiration along the way.

Browse through the TimberKraft Custom Homes gallery, collect some ideas of what you would like to see in your structure, while also keeping in mind the Ten Questions To Ask Yourself Before Building a Custom System-Built Home.

After glancing through the ten questions, start constructing a broad list of the specific needs of your structure. Such as: bedrooms, bathrooms, square footage, garage space, etc. This will help our designers match the custom design to the function of your everyday lifestyle.

If you haven’t started looking for land for your proposed project, this is also a great time to search out property. That way, we can help custom design the structure to help fit your site perfectly.

Design Proposal

Step 2:

Once you have gathered enough inspiration and feel comfortable with your proposed design idea, it’s time to reach out to a TimberKraft Custom Homes.

At this point, your designated project manager will set up a meeting to discuss the specifications of your structure. In this meeting, we will discuss your needs and desires in an effort to dial in the square footage of the design, the materials that will be needed, and any other custom specifications.

Your project manager will then construct a proposal based off of the information you have provided us. The proposal will include an estimated custom home material package price. The price will be based off of the Sq Footage of the proposed structure and the materials being used; either Timber Frame, Post and Beam, Log, or Hybrid.

One On One Design

Step 3:

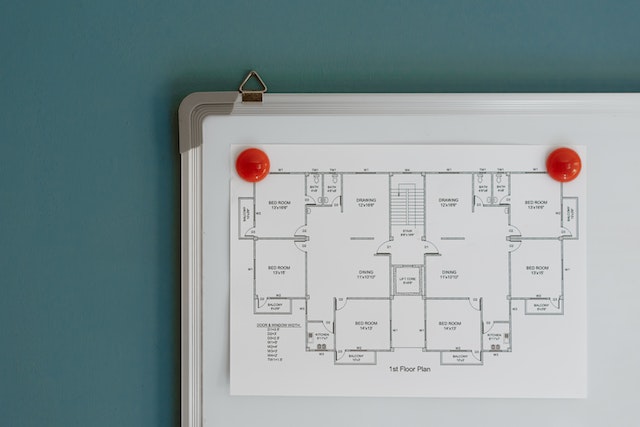

Once we have received your approval on the design proposal, we will take your design ideas and start sketching out an initial design of the structure based on the information you have provided us.

At this point, yourself and one of our luxury designers will be meeting one on one, either in person or remote, to walk through the initial design.

This will include a proposed floor plan, and exterior sketches (elevations).

This is where you can refine each individual aspect of the design (floor plans, elevations, etc…) to suit the needs and desires of yourself and your family.

When you begin to feel comfortable with the design, we can then start to move forward with a full set of 3D Renderings with custom floor plans (schematic drawings) to match.

Design Approval

Step4:

After working hand in hand with one of our luxury design specialists, we hope to obtain your approval and move forward with prefabrication of the structure.

At this point, the designs will be handed over to a structural engineer. The engineer will help take your design and transform them into a set of stamped, structurally engineered plans, fit to your local code requirements.

Keep in mind, if you do approve your designs and move forward with structural engineering, any changes made to the plans after this point will have a large impact on both cost and timelines. Every change needs to be re-engineered, and sometimes it requires an entire re-design.

Construction Detailing & Prefabrication

Phase2:

The second phase in the TimberKraft Custom Homes prefabrication process involves the structural engineering of your designs and the prefabrication of the materials. Follow along, step by step, as we outline the process from engineering, through prefabrication and shipping of the package.

Structural Engineering

Step1:

Once the conceptual designs of the structure have been completed, the designs are sent off to our structural engineers.

At this point, the engineers will be working hand in hand with your designer to take the conceptual designs and piece them together into a set of plans that are specific to your local requirements, regardless of where you are in the country.

Meanwhile, drafts of the shop drawings for all of the timber and SIP paneling components are being constructed so that once the plans are stamped, the prefabrication can begin.

Material Package Procurement

Step 2:

With a stamped set of structurally engineered plans and calculations, we can begin the procurement process of the material package.

The timbers will all be cut to size based on the construction plans. Then, once properly sized, the timbers are hand finished with mortis and tenon joinery. Each timber is then assembled and test fit off site for quality assurance.

Our SIP paneling used throughout the structure will also be prefabricated off site. Each panel is cut and sized individually with all window and door openings accounted for.

This fine tuned prefabrication process allows builders to streamline the assembly of the material package when it arrives on the job site.

Shipping

Step 3:

Once the materials have been prefabricated and test fit off-site, they are ready to be shipped to the property and assembled by the builder chosen for the project.

Your project manager will be in constant contact with the builder to monitor the progress of the project throughout this time frame to ensure everything ships at just the right time.

When the foundation of the structure is nearing completion, the material package will be shipped. This minimizes the amount of time the Timber and SIP components sit on the job site exposed to the elements prior to assembly.

Turnkey Assistance

Phase3:

The final step in the TimberKraft Custom Homes prefabrication process, is seeing the build through to completion. That’s why we provide you with three different construction solutions to help fit your project and provide the ultimate turnkey assistance.

Your Own Local Builder

Option 1:

It’s not uncommon to have a preferred builder in a given area, especially if this is not your first new construction project. That’s why, at TimberKraft Custom Homes, we make it easy to work with any builder you might already have in mind.

When you approach one of our project managers to discuss your build, it is important to let them know if you have a builder in mind. That way, as we get started on the conceptual designs as well as the structurally engineered construction plans, your project manager can vet the builder.

During the vetting process, we will be in contact with the builder to discuss the specific nature of the project as well as their experience with SIP and Timber Frame materials. We also like to make sure that the builder is committed to your project so that the entire process is truly streamlined.

Once we have settled upon the builder, we will begin to discuss timelines for the project and when the materials need to be shipped. Essentially acting as the middleman between the builder and yourself to make sure everything goes as planned, from A to Z.

We Help Source & Vet The Right Builder For Your Project

Option 2:

If you’re new to an area, or unsure of whom you would like to construct your material package, we here at Timber Kraft Custom Homes are happy to help.

When you reach out to a design specialist regarding your project, let them know where you plan to build and if you think you’ll need assistance sourcing the right builder.

That way, while you work one on one with a TimberKraft Custom Homes designer to construct the home of your dreams, we can get to work on sourcing and vetting the right builder in your local area.

The sourcing and vetting process involves reaching out to at least three builders within the proposed location. We discuss with the builder the specifications of the project, the materials being used in construction, as well as their availability and commitment to the project.

If you would like to recommend a local option of your own or a referral from a friend or family member, that is more than welcome. We will help make that connection and ensure they are right for the project.

Essentially, we just want to make sure that the builder has the level of experience needed to construct your project as well as the time and resources necessary to fully commit to the project.

Once we have vetted a few builders in your local area, we will source a competitive bid from each. That way you have some options to choose from in order to maximize your budget.

We’ll Build It For You

Option 3:

The third and final construction solution that we can offer for your material package construction is our In-House option.

TimberKraft Custom Homes in house building partner that we fall on for selected projects nationwide.

With over 25 years of residential and commercial construction experience, TimberKraft Custom Homes Log Homes has constructed hundreds of prefabricated material packages into client’s dream homes.

Based out of Durango, Colorado, Timber Kraft Custom Homes’ highly experienced teams are mobile, and able to travel a majority of the western United States.

Get in contact to see if Timber Kraft Custom Homes is the right fit to construct your material package with ultimate efficiency and quality custom craftsmanship.